Anyone who has worked in rubber compounding long enough knows this: a fast accelerator is only valuable when it remains controllable. I have seen plenty of formulations ruined not by poor raw materials, but by unstable curing behavior and inconsistent dispersion. This is where TETD-80 pre-dispersed masterbatch quietly proves its worth. By combining the proven chemistry of TETD with a polymer carrier system, TETD-80 delivers speed without sacrificing processing safety or consistency—something powdered accelerators often struggle to achieve.

Fast and Efficient Vulcanization with TETD-80

TETD-80 is widely recognized for its rapid vulcanization performance, especially in sulfur-based curing systems. Compared with conventional powdered TETD, the pre-dispersed form allows the active accelerator to become available more quickly and more evenly during mixing and curing.

In practice, this translates into shorter cure times, improved production throughput, and better control over cycle efficiency. For manufacturers operating continuous or high-speed lines, TETD-80 supports faster crosslink formation without introducing unnecessary formulation complexity.

Stable Cure Performance in Rubber Compounds

Speed alone is never enough. What really matters on the production floor is predictability. TETD-80 provides a stable curing profile that reduces batch-to-batch variation, even in complex formulations.

Because the accelerator is uniformly dispersed within the masterbatch carrier, the risk of localized over-acceleration is significantly reduced. This results in more consistent scorch behavior, balanced cure curves, and reliable mechanical properties in finished rubber products. For compounders, this stability means fewer surprises during processing and vulcanization.

Cleaner and Dust-Free Processing

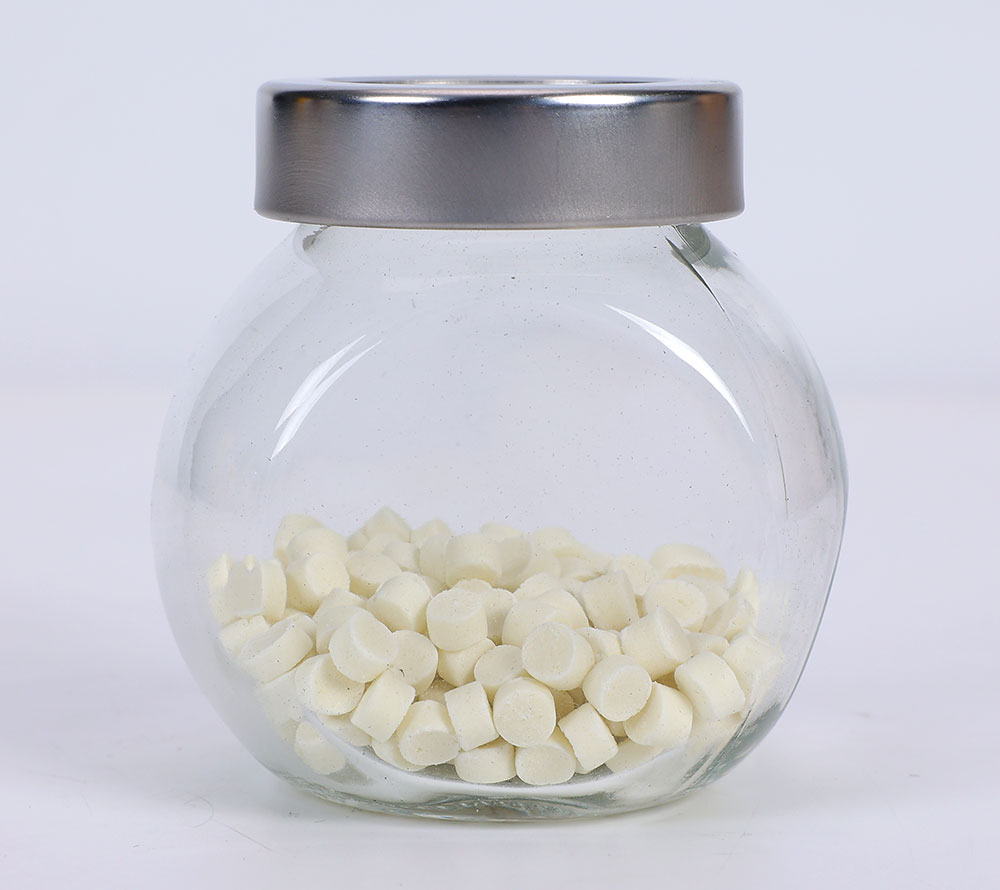

Handling powdered accelerators has always come with challenges: dust generation, material loss, and operator exposure. TETD-80 addresses these issues directly.

As a dust-free rubber accelerator masterbatch, TETD-80 improves workplace cleanliness and safety while reducing raw material waste. The granulated or pelletized form flows smoothly during weighing and feeding, helping plants maintain cleaner environments and better compliance with modern occupational health standards. From an operational perspective, this is one of the most immediate and visible advantages.

Improved Dispersion and Mixing Consistency

One of the most underestimated benefits of TETD-80 lies in its dispersion efficiency. Poorly dispersed accelerators can create uneven crosslink density, leading to inconsistent physical properties and premature product failure.

TETD-80 is designed to disperse rapidly and uniformly within common rubber matrices such as NR, SBR, and EPDM. The result is homogeneous compound structure, smoother processing behavior, and more predictable performance in finished goods. For mixers running high filler loads or tight quality tolerances, this consistency is critical.

Reliable Choice for High-Volume Rubber Production

From my experience, TETD-80 truly shows its value in large-scale and automated rubber manufacturing. The combination of fast curing, clean handling, and stable dispersion makes it especially suitable for tire components, hoses, seals, and other industrial rubber goods produced in high volumes.

By minimizing processing variability and simplifying accelerator handling, TETD-80 helps manufacturers maintain steady output while controlling long-term production costs. It is not just an accelerator—it is a process-stabilizing tool for modern rubber plants.

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.